Description

Technical Specifications

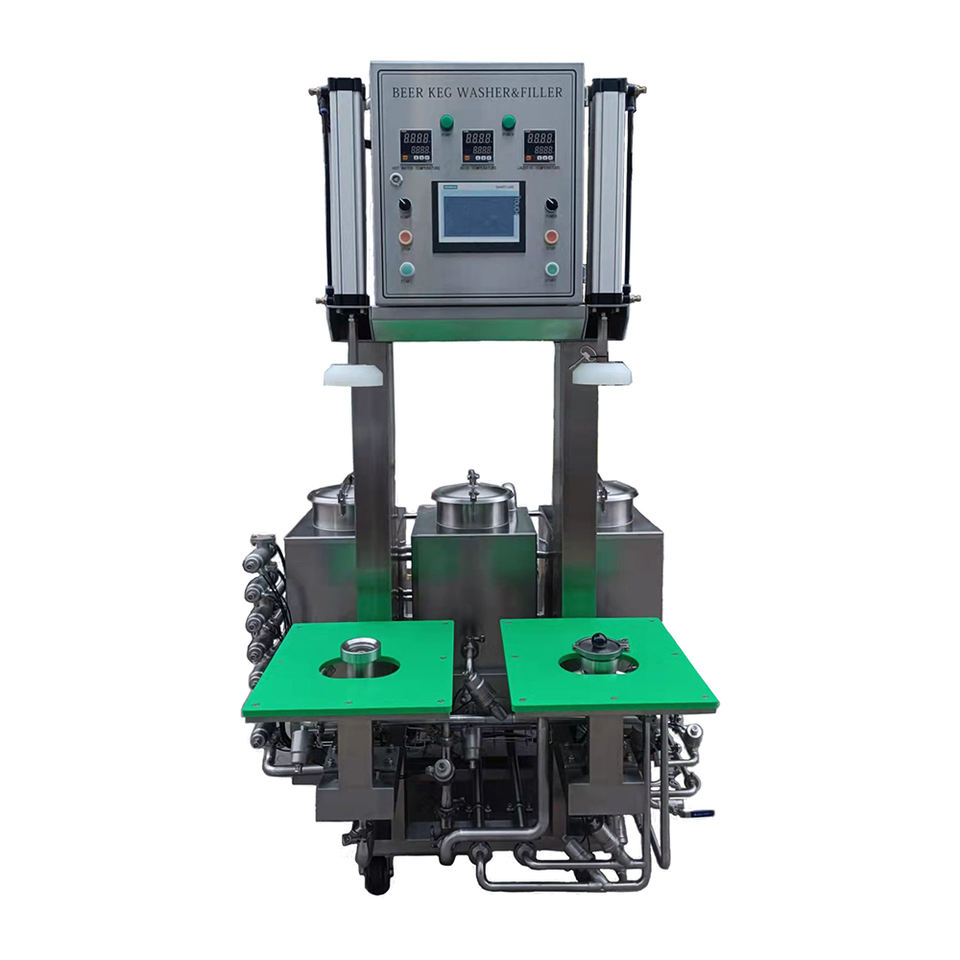

| Keg Filler/Washer Monobloc with Fixed Platform | |

| Capacity | 30-40 KPH (Kegs per Hour) |

| Heads | 2 heads, 1 for washing, 1 for filling |

| Tanks | 3 tanks: caustic liquid tank, sanitizer liquid tank, hot water tank |

| Power Supply | 380V/50Hz, or customized |

| Power Consumption | Steam heating 3kw; electrical heating 18kw |

| Applicable Kegs | Diameter Φ250-Φ500, height H360-H600 |

| Heating Method | electrical, or steam heating |

| Platform | Fixed |

| Dimensions | 1200mm×1600mmm×2000mm |

| Net Weight | 380Kg |

| Features | 1. Siemens control unit, fully automated process, parameter adjusted by touch screen, process displayed on touch screen; 2. Washing & filling process completed in one machine; 3. Pneumatic double action angle seat valves, with sensitive and stable actions; 4. Unique pressure hold system, stable with low beer loss; 5. With CIP recycle piping. |

| Procedures | Filling process: Keg positioning >> open keg spears >> fill >> stop >> rinse spears >> take off kegs; Washing process: Press >> open keg spears >> discharge residual liquid >> clean water rinse >> caustic liquid rinse >> hot water rinse >> hot water rinse >> steam >> CO2 pressure >> take off kegs. |

Reviews

There are no reviews yet.